More practice

Thursday, April 30, 2015

Tuesday, April 28, 2015

Monday, April 27, 2015

Fishmouth tubing....take 3

I tryed a combination bench grinder and dremel tool tonight. The two work very well together. First I mark the angle of the joint and the center line. Then grind most of the material off. This naturally starts to round a groove in the tubing.

Then i used the dremel with a 5/8" bit which wants to center in the groove, as I round the groove to fit the contour of the longerons which is mostly 5/8". A little test fitting results in a fairly tight joint with the appropriate angles. Much like sanding wood joints, it takes a little practice. I feel like I have a good system in place now.

90 degree right angles proved to be slightly more challenging for me, which I was not expecting.

Saturday, April 25, 2015

Sunday, April 19, 2015

Saturday, April 18, 2015

Sunday, April 12, 2015

Thursday, April 9, 2015

Wednesday, April 8, 2015

Monday, April 6, 2015

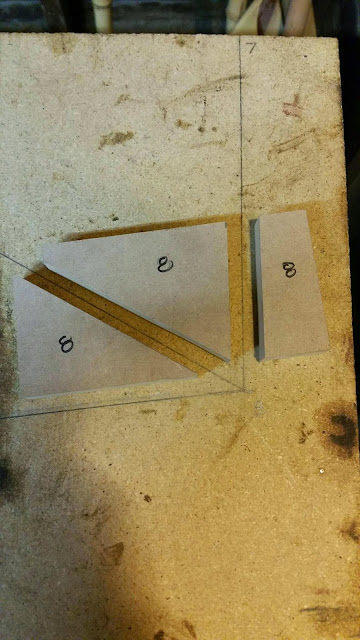

Tubing station

Trying out a little station for fishmouthing tubing. Put down angles up to 90 degress and made a holding tray to elevate the tubing to the correct height. I am hoping this allows better control and more precise joints then would be able with just an angle grinder. Time will tell if this will work.